TM 10-5410-228-24

2.15 FRAME AND GENERATOR.

This task covers:

a. Disassembly

b. Assembly

INITIAL SETUP

Tools/Test Equipment:

Equipment Conditions:

Shop Equipment, Automotive Maintenance and

HMT disconnected from ECV, if required.

Repair (Item 38, Appendix B)

Equipment removed from HMT.

Drill, Electric (Item 6, Appendix B)

Personnel Required: (2)

Drill Set (Item 5, Appendix B)

Gloves (Item 16, Appendix B)

References:

Goggles (Item 17, Appendix B)

TM 9-2330-392-14&P

Riveter, Blind, Hand (Item 34, Appendix B)

Engine Lifting Sling (Item 41, Appendix B)

Materials/Parts: (Cont.)

Automotive Maintenance Stand (Item 48,

Twenty-Eight Blind Rivets (Item 75, Appendix E)

Sixteen Blind Rivets (Item 80, Appendix E)

Fourteen Blind Rivets (Item 73, Appendix E)

Materials/Parts:

Lockwasher (Item 23, Appendix E)

Ten Lockwashers (Item 30, Appendix E)

One Hundred and Twenty Eight Blind Rivets

(Item 70, Appendix E)

NOTE

For maintenance or repair of HMT frame, wheels, lights, brakes, etc., refer to TM 9-2330-

392-14&P.

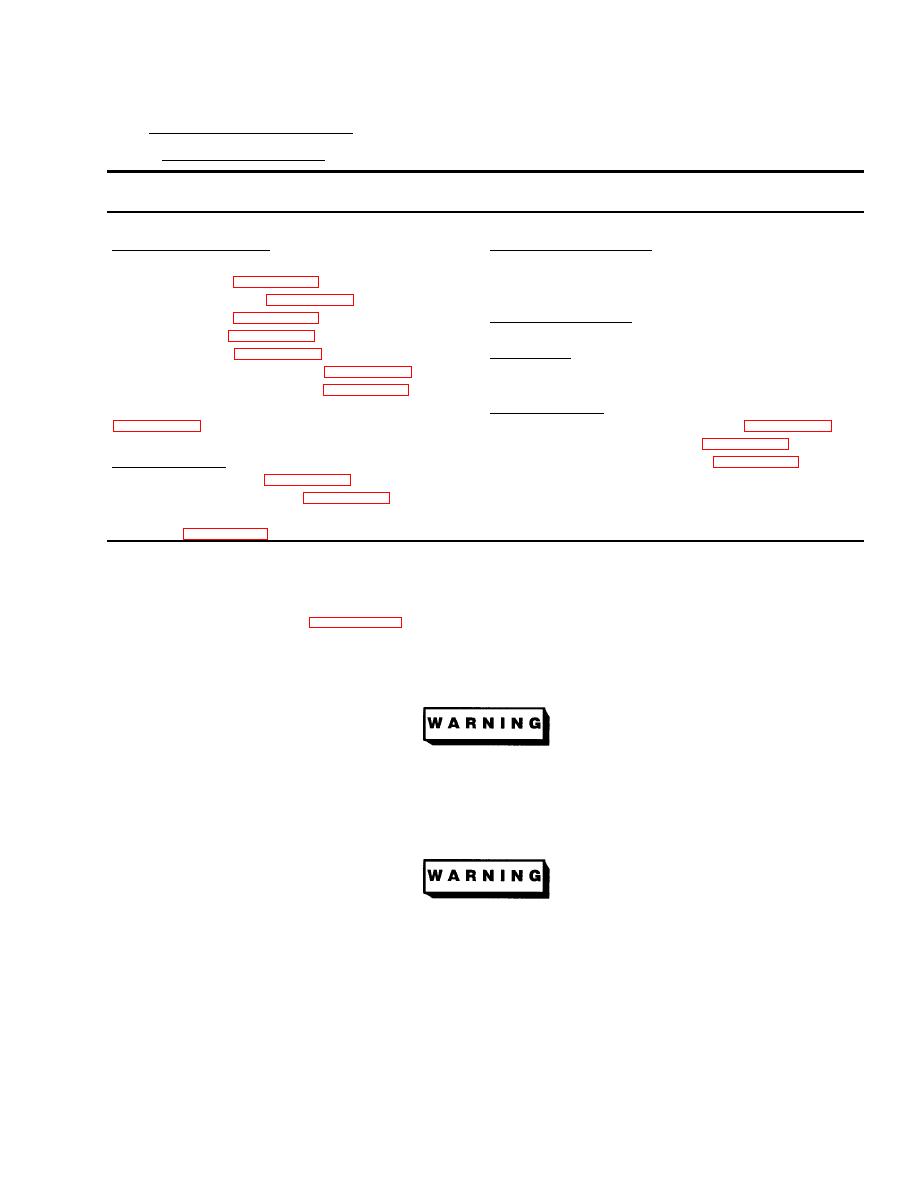

a. Disassembly (Refer to Figure 2-63)

(1)

Disconnect cable assembly (1) from generator (2).

(2)

Remove four screws (3), eight flat washers (4), four lockwashers (5) and four nuts (6) securing

generator (2) to mounting frame (7). Discard four lockwashers (5).

The 10 kW TQG is extremely heavy. Use proper lifting equipment and observe all safety

practices for lifting to prevent injury to personnel.

(3)

Using automotive maintenance stand and chains, remove generator (2) from HMT (8).

(4)

Remove six screws (9), six lockwashers (10) and six flat washers (11) securing mounting frame

(7) to HMT (8). Discard six lockwashers (10).

To prevent injury to personnel, always wear eye protection when drilling. Warning applies to

steps 5 through 15.

(5)

Drill out eight rivets (12) securing two strap assemblies (13) to HMT (8).

(6)

Drill out sixteen rivets (14) securing four strap assemblies (15) to HMT (8).

(7)

Drill out 24 rivets (16) securing three strap assemblies (17) to HMT (8).

(8)

Drill out eight rivets (18) securing strap assembly (19) to HMT (8).

(9)

Drill out 30 rivets (20) and two rivets (21) securing four strap assemblies (22) to HMT (8).