TM 5-3740-214-14

Table 4-1. Organizational Preventive Maintenance Checks and Services (Continued)

M = Monthly

A/R = As Required

Q = Quarterly

H = Hourly

INTERVAL

ITEM

ITEM TO BE INSPECTED

NO. M A/R

Q

H

PROCEDURE

FORMULATION TANK (Continued)

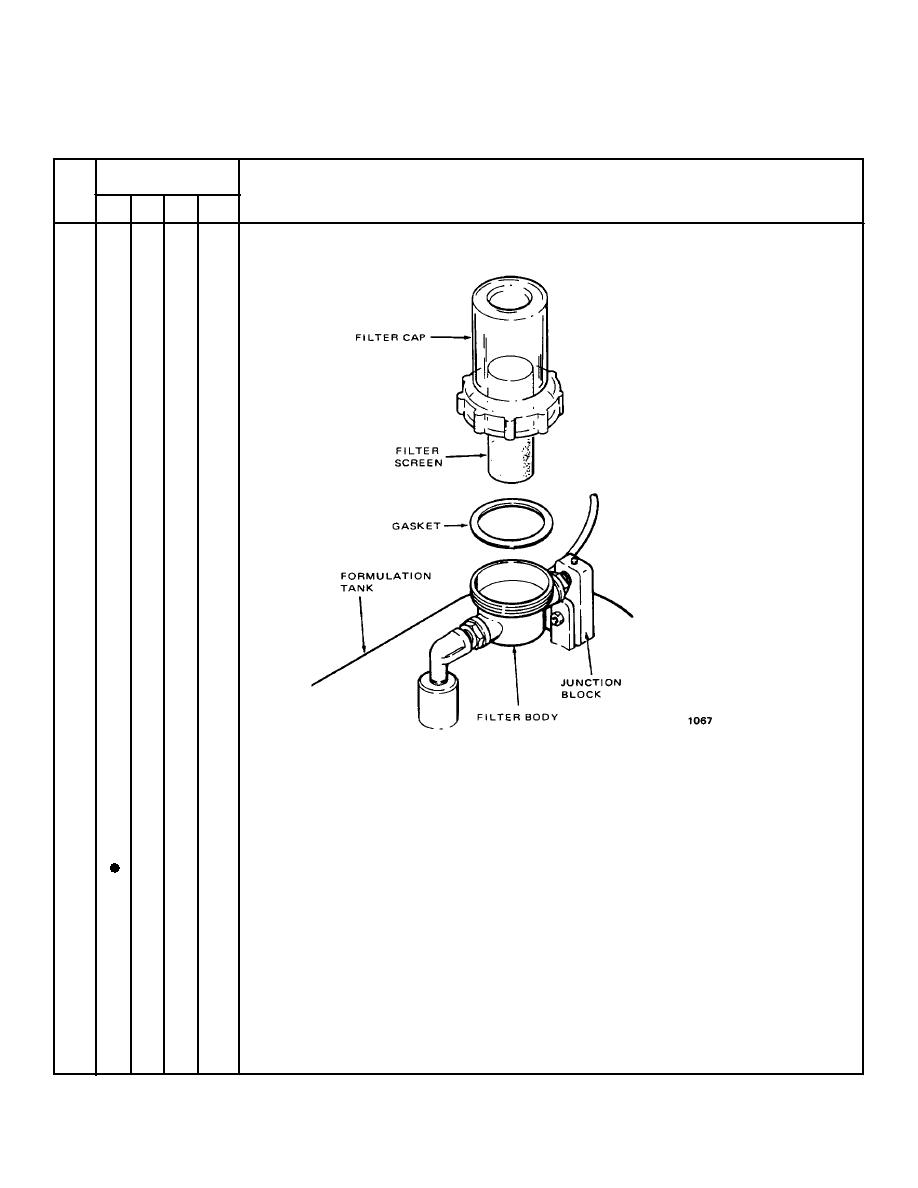

Figure 4-24. Filter Assembly

(2) Reassemble filter. Make sure gasket seats correctly and does not bend, twist or

become pinched in the threads.

13

FLUSH TANK

a. Make sure flush tank is securely fastened to base assembly and engine.

b. Make sure flush tank operates correctly.

(1) Turn three-way valve to flush position.

(2) Unlock flush tank pump handle.

(3) Pump handle up and down twelve times and lock handle. If a pressure does not

build up while pumping notify your supervisor.

4-20