T.O. 33B-1-1

5-29

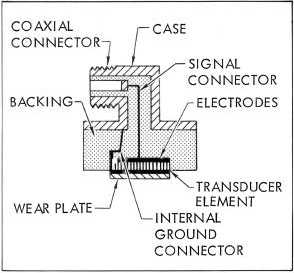

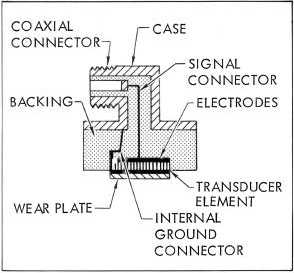

Figure 5-29. Straight Beam Contact Search Unit.

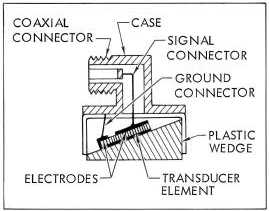

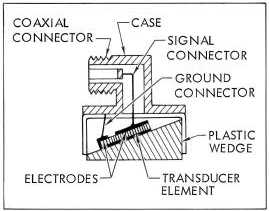

Figure 5-30. Angle Beam Contact Search Unit.

5.2.2.2

Effect of Search Unit on Inspection System Performance.

a. Sensitivity. Sensitivity is the ability of an inspection system to detect small discontinuities. It is

generally rated by the ability to detect a specified size and depth flat-bottom hole in a standard test

block. Sensitivity is unique to each combination of search unit and test instrument. The same model

instruments and search units of the same size, frequency, material, and manufacturing do not always

produce identical indications. For this reason, all inspections must be set up using a series of reference

standards.

b. Resolution. Resolution refers to the ability of an inspection system to separate signals from two

interfaces close together in depth. An example of two such signals is the front surface signal and the

signal from a small discontinuity just beneath the surface. The damping or backing material (see

Figure 5-29) affects the time required for the transducer to stop "ringing" after being excited by a pulse

from the test instrument. Low damping causes high "ringing" resulting in a wide, high-amplitude

front surface signal. This would cause a long dead zone. Signals from discontinuities just beneath the

front surface would be masked by the front surface signal.