T.O. 33B-1-1

The following procedure shall be used to determine the concentration of magnetic particles and to check for

the accumulation of dirt or other contaminants in a suspension. The equipment required is a 100 cubic

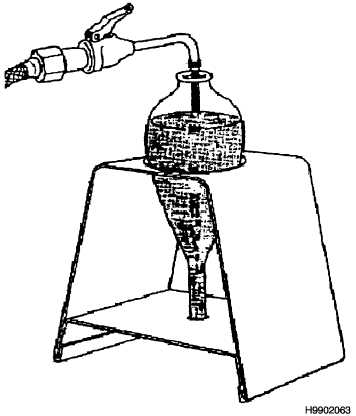

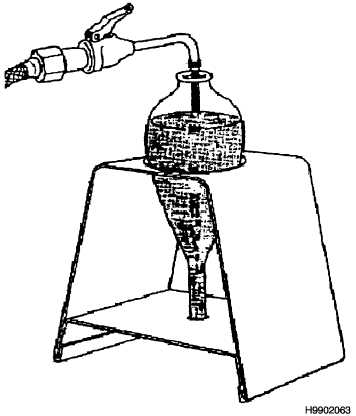

centimeter (cc) or 100 milliliter (ml) pear-shaped, graduated centrifuge tube and stand (see Figure 3-33).

Figure 3-33.

Filling Centrifuge Tube from Hose

a.

Thoroughly agitate the suspension.

b.

Run suspension through the hose and nozzle for at least 1 minute. This is to assure the suspension in

the hose is fresh and agitated.

c.

Fill the 100 cc (100 ml) centrifuge tube with agitated suspension using the hose.

d.

Demagnetize the suspension in the tube to reduce clumping.

e.

Place the centrifuge tube in its nonferromagnetic stand and allow settling on a vibration free surface

for 1 hour for oil baths and 30 minutes for water baths. Inspections or Process Control Inspections

CANNOT BE ACCOMPLISHED prior to the full 1 hour time limit. The suspension concentration

must be within T.O. limits prior to use.

f.

Observe the total level of settled particles at the end of the settling period. The graduated cylinder

reads directly in milliliters. The level of contaminants must be subtracted from the total level to

obtain the concentration of particles (see paragraph 3.5.6.6.3).

3-70

Change 2