T.O. 33B-1-1

SECTION IV

PORTABLE MPI TECHNIQUES

3.4

PORTABLE MAGNETIC PARTICLE FIELD INSPECTION TECHNIQUES.

3.4.1

General.

a.

Portable induced field inspection equipment is generally referred to as either a probe or a yoke. These

terms are synonymous and differ only due to manufacturer’s nomenclature. This category of

inspection equipment is described here in conjunction with the techniques for their use and

application.

b.

Magnetic yokes are small and easily portable. They are easy to use and are adequate when testing

small castings or machine parts for surface cracks and for weld inspection. They induce a strong

magnetic field into that portion of a part that lies between the poles or legs of the yoke. The induced

field f lows from one leg of the yoke to the other regardless of the style or leg configuration. Yokes or

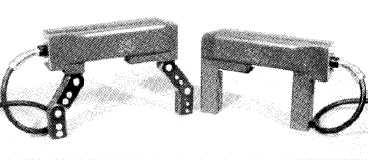

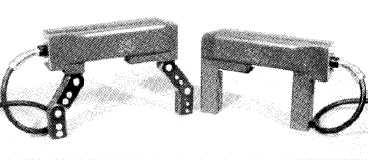

probes are available with either fixed or articulated legs as shown in Figure 3-29.

Figure 3-29.

Portable Induced Field Inspection Equipment

c.

Either dry powder or wet magnetic particles may be used in conjunction with a yoke for the detection

of discontinuities. Yokes are available for operation from a 115 volt, 60-hertz AC outlet, or from a 12

volt DC battery. A permanent magnet yoke is also available, permitting inspections to be performed

without the use of electric current.

d.

Deleted.

3.4.2

Capabilities and Limitations.

a.

The units are designed for simplicity, ease of handling, and operation by one person. They may be

used on machine-finished surfaces, as well as castings and weldments fabricated in a variety of

configurations. The units induce a strong magnetic field at the surface of the part being inspected.

Since no current is f lowing through the part being subjected to inspection is impossible to overheat or

burn the part. The f lexibility of a yoke with articulating legs is greatly increased permitting

inspections to be performed on parts of varied configurations.

b.

Yokes or probes are limited to the detection of surface and near surface discontinuities only. They

should not be used for deep-seated, subsurface discontinuities due to the limited penetration of the

induced magnetic field. Because of their size they cannot be used with a 100% duty cycle. Rather,

they are limited essentially to spot-checking and occasional sample testing rather than continuous

production testing. Under optimum operating conditions, the fixed leg yoke has a limited inspection

area governed by the distance between and immediately surrounding the legs. The moveable or

articulated leg yoke can inspect either a larger area (legs apart) or detect finer discontinuities by

concentrating the magnetic field in a smaller area (legs closer together).

Change 2

3-49