T.O. 33B-1-1

2-78

2.7.4.1.4

Black Light Fixtures.

CAUTION

Black light bulbs SHALL NOT be operated without filters. Cracked, chipped or ill-

fitting filters SHALL be replaced before using the lamp. High intensity "super"

black lights that use bulbs with integral filters SHALL have a splash guard attached

to the front of the lamp housing to prevent accidental implosion of the bulb. This

splash guard SHALL be the manufactured item.

A high pressure, mercury vapor, black light bulb requires a housing, filter, regulating ballast or transformer and

connecting cables or wires. The housing, which may be metal or plastic, serves several functions:

a. Hold and protect the bulb.

b. Hold and support the filter.

c. Prevent leakage of unwanted visible light.

d. Permit directing the beam on the surface to be inspected.

e. Provide a means for handling the bulb.

2.7.4.1.4.1

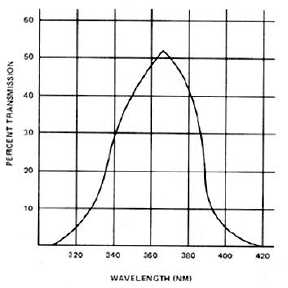

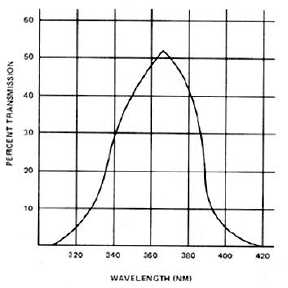

The filter is a special material that prevents the passage of short wavelength ultraviolet and long wavelength visible

light. The filter transmits ultraviolet between 320 nm and 400 nm. This wavelength causes maximum florescence of

the penetrant dyes. Black lights used for penetrant inspection SHALL have a peak wavelength between 340 and 380

nm. Figure 2-30 shows the transmission characteristics of Kopp 41 filter glass. Filters for penetrant inspection can be

either a smooth or fluted surface. The fluted surface provides a slightly larger focused spot than a smooth surface filter.

A current regulating ballast or transformer is required for proper functioning of the bulb.

Figure 2-30. Transmission Curve for Kopp 41 Glass.